Technical case study #1 - Project setup

This technical blog marks the beginning of a series, in which we share more technical details of our generated design. We will unpack one sample project, from project setup and specifications, to calculating gravity and lateral force requirements, to detailing system designs and material selections.

We know that for a structural engineer, trust isn't given; it's earned through rigorous, verifiable calculations. Our goal is to transparently detail the engineering principles and computational processes behind our Generative Design copilot.

Project Setup

The project that we will work together is a single-family house located in Medina, WA with zipcode 98039. The property owner wanted to build a new house on the land that they recently acquired, and the architects designing this property approached us for structural design.

Side views

The property consists of two floors above the ground and one basement, which also contains a garage. Here are some rendered images of the side views of the property.

Floor plans

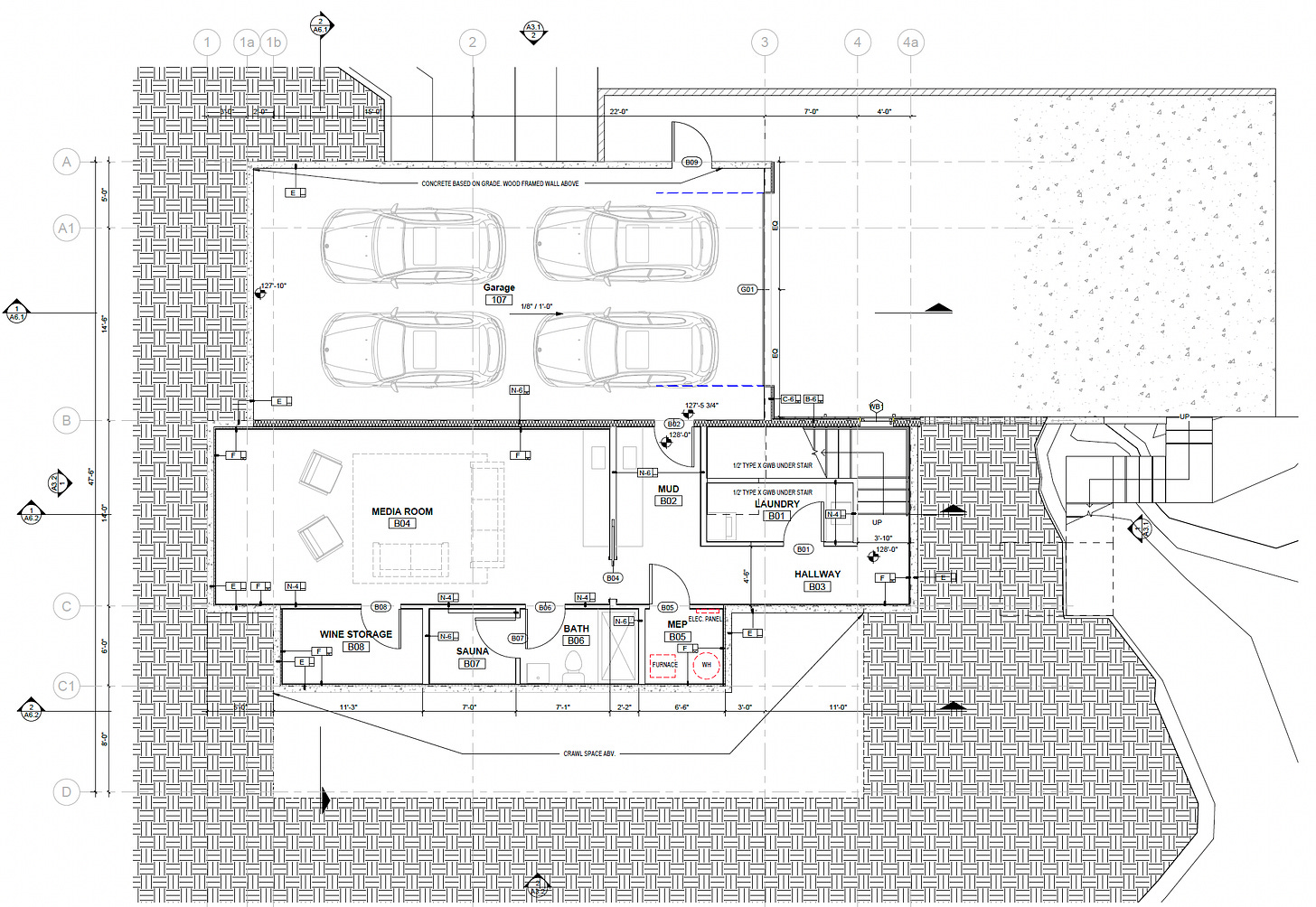

The Basement is dominated by a four-car garage with a concrete slab base. Adjacent to the garage is a media room. The layout also includes a mudroom, a laundry room with under-stair storage, and a central hallway. Wellness amenities consist of a sauna and a bath, complemented by a dedicated wine storage room. An area for mechanical, electrical, and plumbing systems, including a furnace, is designated, with a crawl space noted above a portion of this level. Stairs provide access to other floors, and perimeter details suggest a below-grade construction.

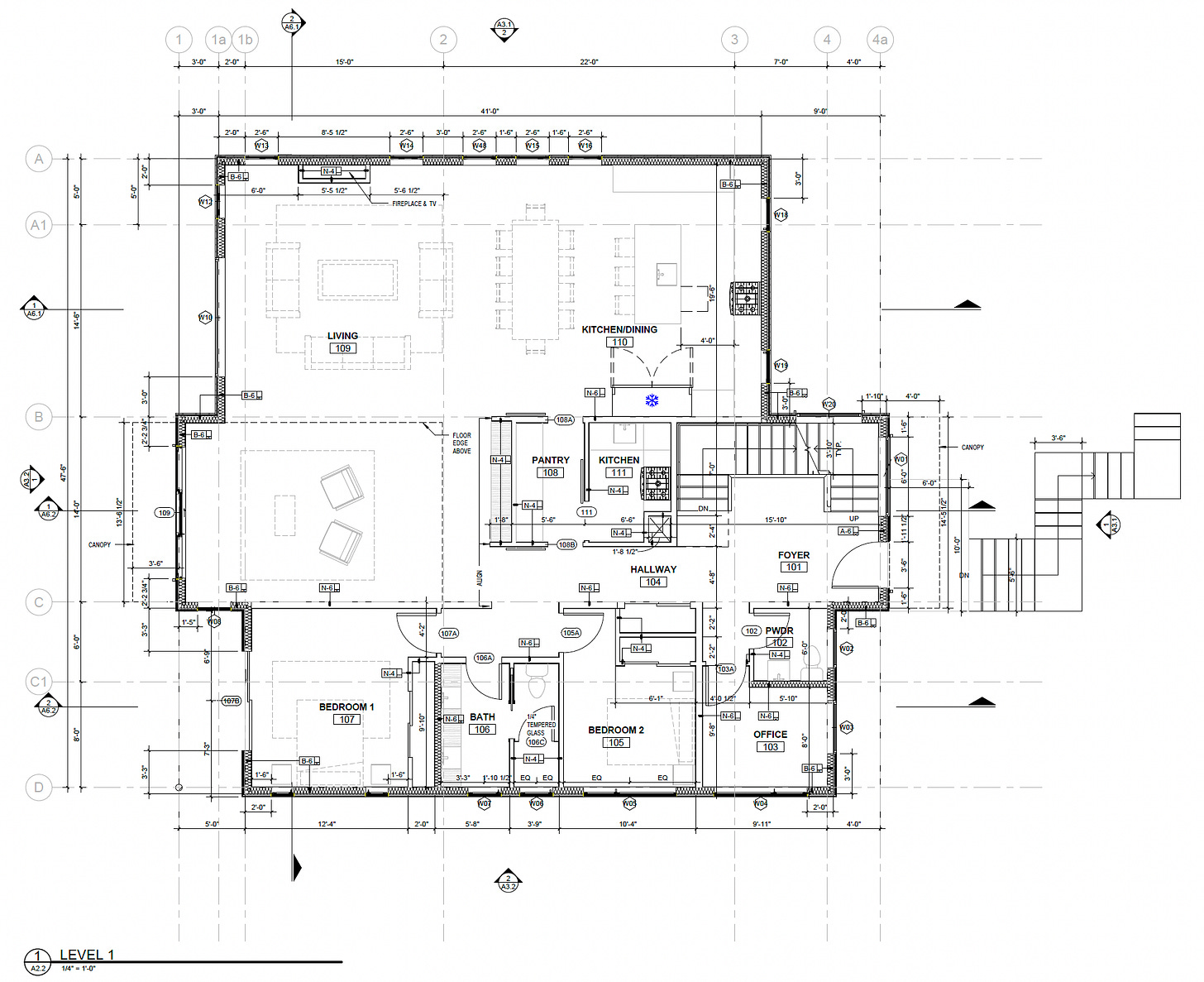

On Level 1, the main entry opens into a foyer, which provides access to a nearby office and powder room. A central hallway extends from the foyer, leading to two bedrooms. One bedroom features an en-suite bathroom and a walk-in closet, while the second bedroom is situated near a separate full bathroom. The primary living zone is a spacious, open-concept area that integrates the living room, dining space, and kitchen, the latter being supplemented by a pantry. A dedicated laundry room is also included. Stairs located near the entrance indicate access to additional levels within the structure.

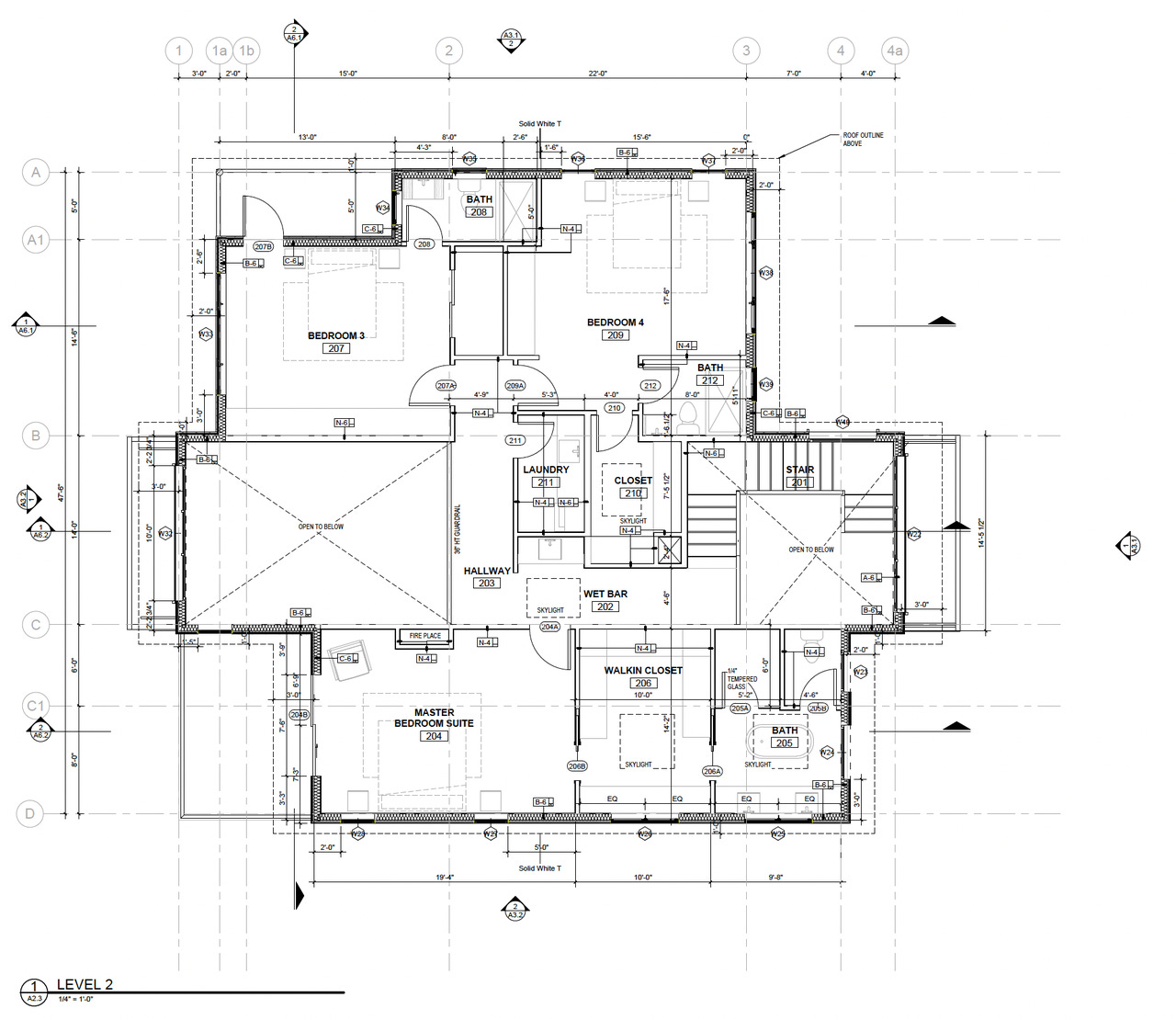

Level 2 features a large master bedroom suite complete with an en-suite bath and a spacious walk-in closet. Two additional bedrooms are present: one has a private bath and a balcony, while the other is located near a separate full bathroom. A central hallway connects these spaces and leads to a laundry room and a wet bar. Part of Level 2 will be open to the living room on the floor below. Stairs provide access to and from this level.

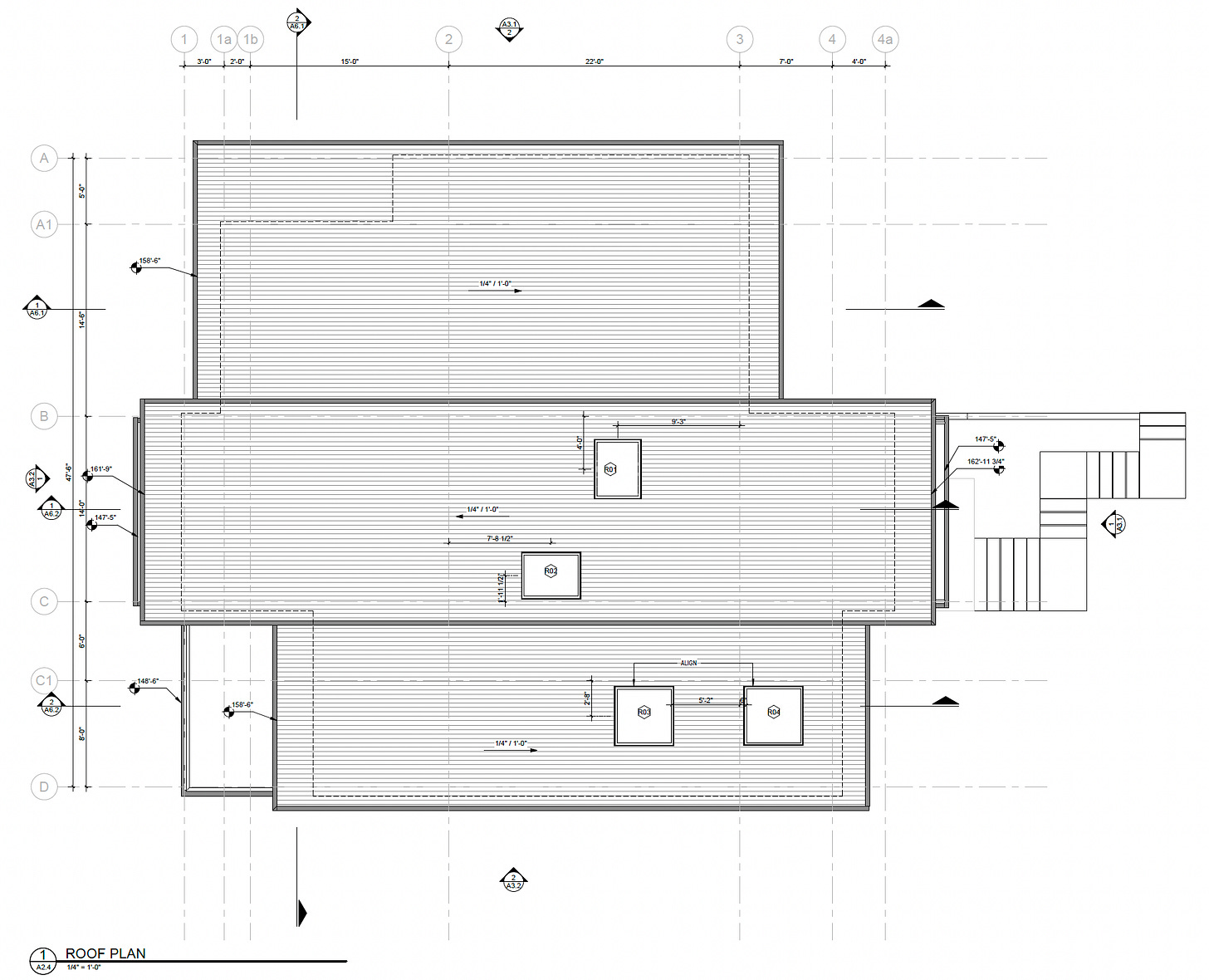

The roof is made of three sections of flat roofs at different elevations. Some sections of the room also have multiple roof windows for light.

We receive the architectural drawings in both AutoCAD and PDF formats.

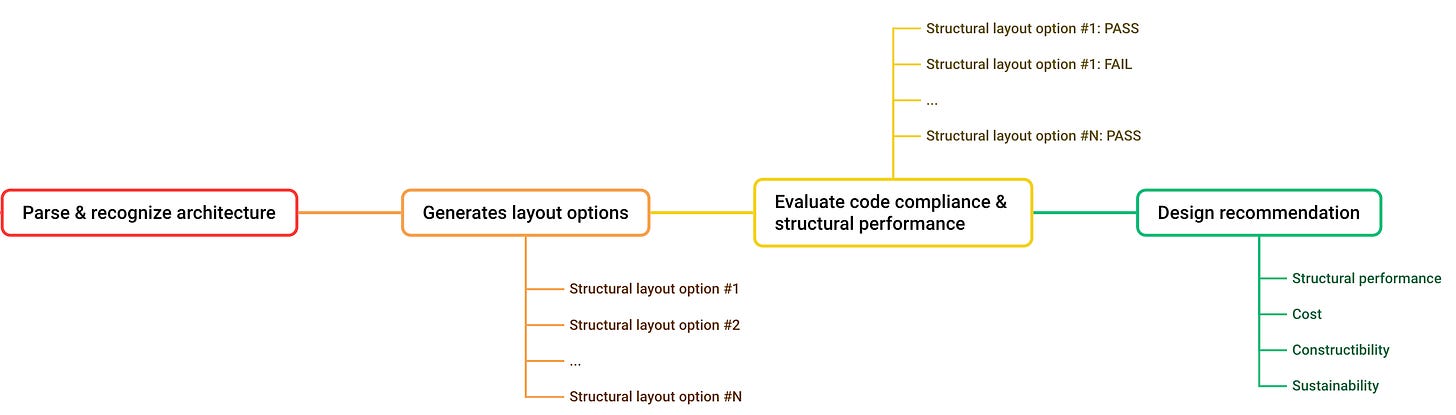

Design Methodology

When Genia Structural CoPilot receives an architectural drawing, it will first parse the CAD file, recognizes key architectural elements relevant to structural design, generates structural layout options, perform analyses on structural stability of each, and eventually recommends top 3 design options balancing structural stability, cost, constructibility and sustainability.

Parse Architectural Drawings

Architectural drawings are typically well-organized but can be messy at times. We've often been asked by our clients what assumptions we make about the architectural drawings. Do the drawings need to follow a specific naming fashion? Do they need to be separated by floors? Do entities need to be put on separate layers?

Well, we realize that putting a strong requirement on drawings, while improving recognition accuracy at margin, kind of defeats the purpose if someone has to spend hours cleaning the drawing before being able to use our product.

Therefore, we only make two minimum assumptions about the architectural drawing and develop a proprietary model that is robust enough to handle the rest of the edge cases. These two assumptions are:

Architectural drawings need to be well-layered, which means entities like walls, windows, doors and roofs can be found in separate sets of layers. We rely on layer names as additional cues but do not require a specific naming fashion.

Architectural drawings need to be well-formed. As an extreme example, we've seen a cupboard attached to a wall, and the interior perimeter line of the wall was omitted and borrowed from the cupboard. In such case, we will NOT be able to reinstall the missing wall line here and will result in a non-enclosed wall element, leading to an error in our parsing stage.

When we parse an architectural drawing, we look for elements like walls (in particular, structural walls), windows, doors, roof line, opening areas, and decks. We also recognize areas that need support of joists and trusses. We then feed this parsed architecture into our generative design pipeline.

Structural Layout Options

Once the generative network receives the parsed architecture, it explores many different layout options.

The generative pipeline follows a similar approach as human engineers: It designs the gravity system from the top to the bottom, first placing trusses and/or rafters to support the roof and then designing the structure one level below by taking the roof load distribution into consideration. It iterates in such fashion for every floor until the whole building design is complete.

For the lateral system, we look at the building holistically across floors and try to identify common "shear bands" (aka "shear line" or "braced wall band") in both x and y directions. We then place necessary structural elements to complete the design within each shear band.

Code Compliance & Structural Analysis

For each one of the generated design options, we evaluates its structural performance and building code compliance, filtering those options that meet the minimum requirements.

Currently we support building codes in the United States and Canada. For the US, we follow the International Building Code (IBC), with the numerical requirements coming from the ASCE 7 Hazard Tool API. By specifying the location of the property, we obtain the building code requirements covering seismic, snow, rain, and wind. For Canada, we support the National Building Code of Canada (NBCC). Both IBC and NBCC are performance-based.

When we analyze structural performances of the generated design, we first calculate the force requirements for wind and seismic, based on the exterior contour of the property. We then evaluate the structural performance of the designed lateral and gravity systems, both force demands and capacity by selecting the best materials in our product catalog to meet the force requirements. We will cover more details in the next three articles.

Design Recommendation

In the end, among those structural design options that pass the minimum building code compliance check, we recommend top 3-5 different structural design options, balancing:

Structural stability—How much buffer the designed structure has.

Cost—How much our designed structure will cost. This is only a directional guide, as we are not yet integrated with the local distributor network.

Constructibility—The fewer number of SKUs we use in this design, the easier the construction could be.

Sustainability—The less material we use in volume, the more sustainable the building is.

Typically, we will recommend at least one option that is cheapest with the least material use and cost, one other option that has the most extra buffer for structural stability and inevitably uses more material and is more expensive, and a few options in between.

For every recommended design option, we will provide the structural drawing in CAD format, as well as a calculation sheet in PDF that contains all structural analysis details.

In the next article, Genia Co-founder Robin Li will give you a walkthrough of one of the generated structural design for this sample project in Medina, WA.

About the Authors

Robin Li is the Co-founder and COO of Genia and now leads product management. After graduating from University of British Columbia, Robin started off his career at Arup as a certified structural engineer, where he designed structures for a high-rise casino hotel in Macaw. Later, he returned to Canada and designed 100+ low-rise and mid-rise structures, including high-end custom homes in timber. You can find Robin on Linkedin or email him at robin@genia.design.

Calvin Zheng joined Genia in 2024 as a product manager. He holds a master’s degree in structural engineering from UCLA and has 5 years of experience designing structures in Los Angeles, first at JCE Structural Engineering Group and later at KPFF.